Antimicrobial ceramic products

In this era of pursuit of beauty and health, original ceramic products have been difficult to meet consumer demand, and antibacterial functional ceramics have become a consuming trend.

Then, how to choose antibacterial additive and how to apply?

The answer is it must meet the rigid requirements of development, and it must be able to pass industry standards and authoritative inspections and tests; in this way, there must be accurate and customized solutions.

- Selection of antibacterial additives for ceramic

Ceramic products such as ceramic tiles and sanitary ware are all durable products. To increase the antibacterial function of them, the antibacterial additives must be long-lasting and long-acting to ensure that the antibacterial ceramic products can still have good antibacterial properties over a long service life.

There are many types of antibacterial additives, and the antibacterial mechanisms of them are similar and also different. In addition to antibacterial, some also have functions such as anti-mold and air purifying. Silver antibacterial materials are mainstream antibacterial agents, which can enable the surface of ceramic products long-acting antibacterial function, controlling the concentration of pathogens below a low level, and achieving environmental protection and self-cleaning for a long time.

To meet the high-temperature calcination, uniform distribution, discoloration and other tough requirements to achieve long-term antibacterial function, Zirconium Phosphate carrying Silver antibacterial additives are ideal option.

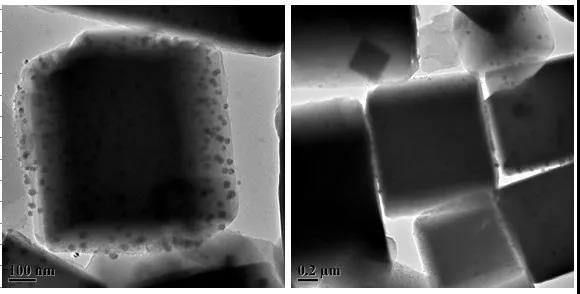

▲Silver ions are firmly adsorbed on the cubic zirconium phosphate carrier

Let’s take cubic zirconium phosphate carrying silver ion as an example. The particle size of this is D50<1.2um, the moisture content WT%≤0.8, PH value 4.5±0.5, the ion exchange rate is very high, and the chemical stability is excellent.

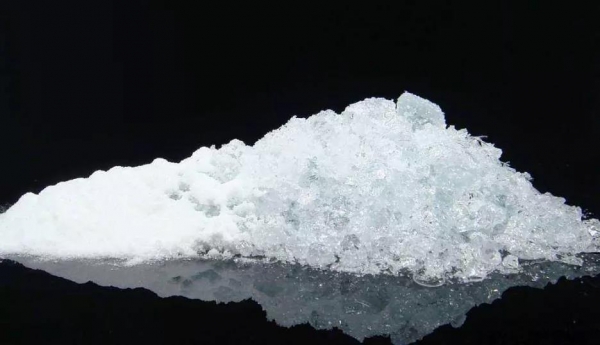

The most important thing is that it can withstand high temperature of 1300° and yellowing resistance. During the development and preparation, adjust the addition amount of zirconium phosphate carrying silver according to the calcination temperature, the antibacterial agent can be uniformly and stably distributed on the surface of the ceramic product.

▲ Can withstand 1300° high temperature calcination, and evenly coat the ceramic with a layer of antibacterial film

Another option is Antibacterial powder for ceramic made with Zirconium phosphate carrying silver, which enable ceramic products antibacterial function, and can reach the level 0 anti-fungal standard. This can be applied for ceramic tiles, toilets, wash basins and other building materials and sanitary products.

- Application and preparation of antibacterial ceramics

There are two methods for preparing antibacterial ceramics: one is to add silver antibacterial additives to the ceramic glaze in a certain proportion, and then coat it on the surface of semi-finished ceramic products, and then calcinate at high temperature to obtain antibacterial ceramic products. Another one is to spray antibacterial agent on the surface of ceramics and coat it with a photocatalytic antibacterial film.

▲ Mix Silver antibacterial additives with ceramic glaze for coating

The two preparation methods are very simple, and will not add any complicated process. You only need to choose suitable antibacterial agent according to the characteristics and cost of the ceramic product. The application of silver antibacterial materials does not change the characteristics of the ceramic glaze itself; and enables the ceramic products antibacterial functions, making the surface smoother and better quality.

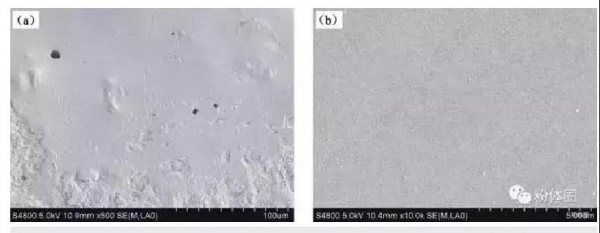

▲ Comparison of SEM images of antibacterial ceramic surface (a, ordinary ceramic, b anti-bacterial ceramic)

The process is simple, and the antimicrobial ceramic can achieve better quality; however, the difficulty lies in the additive amount, as the temperature of the kiln and the calcination time determine the additive amount. This requires precise and customized solutions by professional engineer and whole-process tracking in order to achieve the effect. Therefore, from the beginning of material selection, it is necessary to check whether the product technology, solutions and services of antibacterial agent suppliers are professional.

Ceramic products made with silver antibacterial materials have an inhibitory effect on more than 650 pathogens including Escherichia coli, Staphylococcus aureus, dysentery bacillus, and dermatophytes. They can also suppress the residual of some viruses and prevent large-scale infections Occurrence, thereby safeguarding family and public health safety.

- Experiment and testing of antibacterial ceramic

The antibacterial ceramic products must pass the authoritative inspection and test and reach the industry standard before they can be marketed. To achieve the effect, the following bacteriostatic zone experiments and test reports of ceramic products are used as reference:

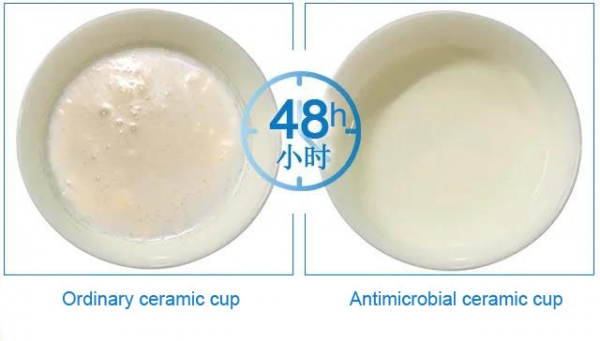

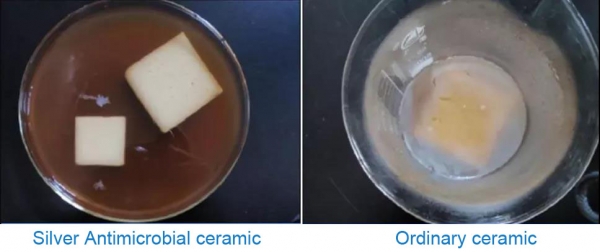

▲ In the 48-hour effect experiment of the antibacterial ceramic cup, it is obvious that the milk on the ordinary ceramic cup has obvious agglomeration and appears to be sour and rotten; while the milk in the silver antibacterial ceramic cup has not changed much and is still fresh.

Check the antimicrobial ceramic solutions by https://esantimicrobial.com/portfolio_catagory/coating-ceramic/.

▲In the antibacterial ceramic bacteriostatic circle experiment, the ordinary ceramic sheet is covered with bacteria and mold; but the silver antibacterial ceramic sheet has not changed.