Project Description

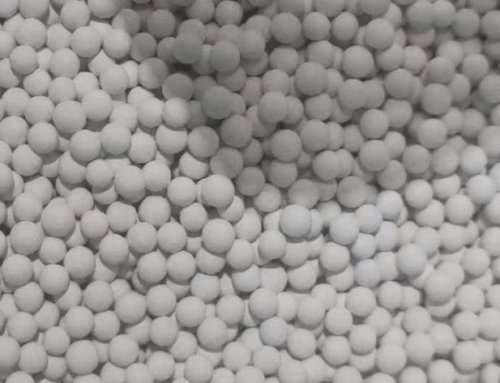

Product Introduction

Calcium sulfite dechlorination balls are mainly used to remove residual chlorine in water bodies. It only takes 0.8 seconds to remove 99% of the residual chlorine. Compared with traditional activated carbon to remove residual chlorine, calcium sulfite has the advantages of high efficiency, safety, high temperature resistance, and no bacteria.

Calcium sulfite and other natural raw materials are made by special characteristics and firing process. It is a high-tech water treatment product of biological and physical technology. This product can effectively remove residual chlorine in water instantly, purify and mineralize water quality, and adjust the pH value of water.

Principle of removing residual chlorine: The final reaction products of treating residual chlorine in water with calcium sulfite balls are calcium sulfate (CaSO4) and calcium chloride (CaCl2).

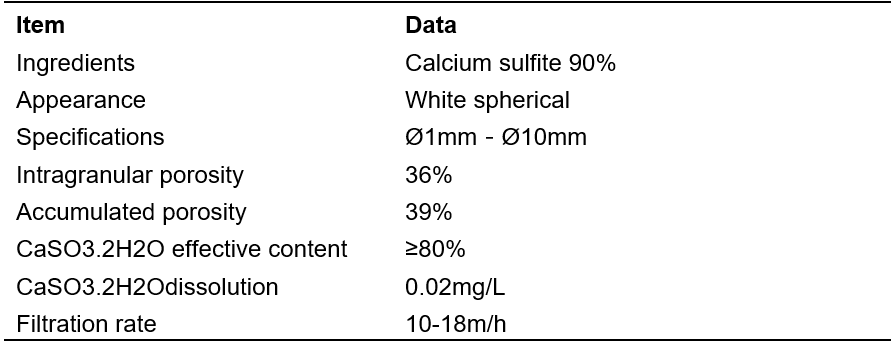

Technical Data

Usage

Recommended dosage:

Recommended dosage:

Shower: 15-30g; Pet water dispenser: 20-30g; Faucet: 25-50g; Water purifier: 100-300g For carbon rods, Dechlorination balls need to be customized separately.

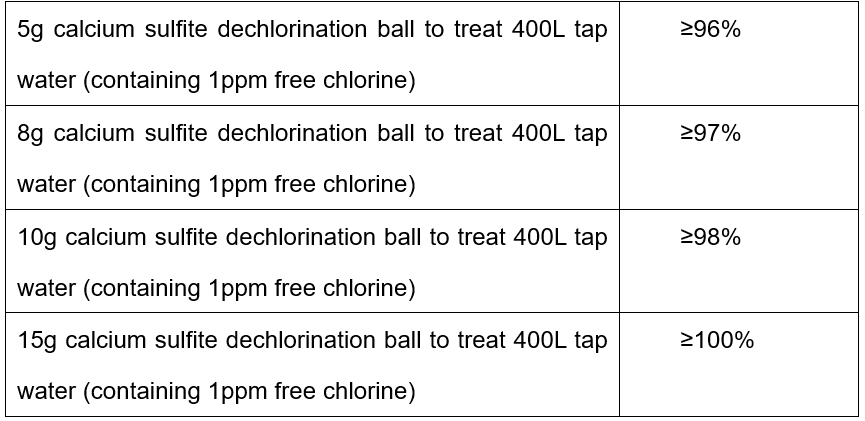

Performance test

Calcium sulfite dechlorination balls (starting with water flow, 2500L of water flow) full-process spiked residual chlorine removal rate test.

Test method: Residual chlorine removal rate: Based on GB/T35937-2018 “Performance test method for drinking water treatment equipment for household and similar purposes” (4.5.5 Purification efficiency) & GB/T5750.11-20061.1 “Standard test method for disinfectant indicators of drinking water”.

Packaging/Storage/Transportation

25kg/bag (can be customized); non-dangerous goods, kept at room temperature away from light, sealed and moisture-proof; avoid storage with strong oxidants or strong acids and alkalis during the process.